Whatever you call them – Checklist, Inspection, Audis – they’re a fact of life in hospitals, factories, maintenance depots, toolshops and many other workplaces. Their purpose is quality control: to help reduce normal human error and deliver a product or service consistently, correctly and safely.

In a stark example that proves this, the World Health Authority introduced a checklist called the Surgery Safety Checklist which reduced the complications and mortality rates for surgical procedures by more than 40%. The idea for that checklist came from a book titled The Checklist Manifesto, where the author (a surgeon himself) makes the point that it’s easy for a competant nurse, or press operator, or pilot to make a mistake in a high pressure, stressful environment. Checklists are simply a device to help avoid those mistakes.

Checks and actions are disconnected

This is familiar background for lean teams, where checklists are a core part of the daily routine. They’re typically scheduled (daily, weekly, monthly, annually) and a team member picks up the checklist at the allocated time and steps through each item. However, this is only half the task. Teams won’t extract the full value of checklists until they are effectively following up and closing out the exceptions and non-conformances. Based on my own experience in manufacturing and healthcare, this is where most teams stumble.

Keeping track of the follow-up actions – often referred to as corrective and preventative actions (or CAPA) – is difficult. That’s due to the nature of the modern workplace and organisation. Actions from one checklist can be assigned to different teams, in different locations, with different priorities. Actions may be tracked on whiteboards, email, spreadsheets or verbally at huddles. The risk is that exceptions are not addressed in a timely manner, or perhaps at all. Even when they are addressed, if people don’t get feedback from the exceptions they’ve raised, then they think that nothing is ever done. That impacts on engagement, and that’s when quality issues start to creep in.

A checklist for a Checklist system

Here are seven things that an effective checklist system will improve:

- Response times – are the actions clearly communicated? Are people clear on the priority?

- Tracking actions – perhaps the most difficult challenge. Can you review a checklist and understand the progress and status of each action? Are actions visible to all the relevant teams and team members? Is the connection between the checklist and actions maintained?

- Lack of detail – often a written description would benefit from an accompanying photo or video

- Too much admin – double handling, transcribing manual lists

- Siloed data – information that is not centralised cannot be analysed properly. Data on whiteboards is gone as soon as it’s cleared. If it’s in email, then typically only two people know about it. Spreadsheets may only be accessible by one person or team.

- Version control – Different versions of the same checklist in circulation

- Closing the loop – are the action outcomes always communicated back to the person that raised them?

Checklist System best practice

We’ve thought deeply about how modern lean teams communicate and collaborate, the technology they can leverage, and how the checklist system can be more effective. Ultimately, the solution needs a tight integration between the checklist and the actions. More specifically, non-conformances should be visible, clearly linked to each corrective and preventative action, and the status and priority should be driven through lean daily management.

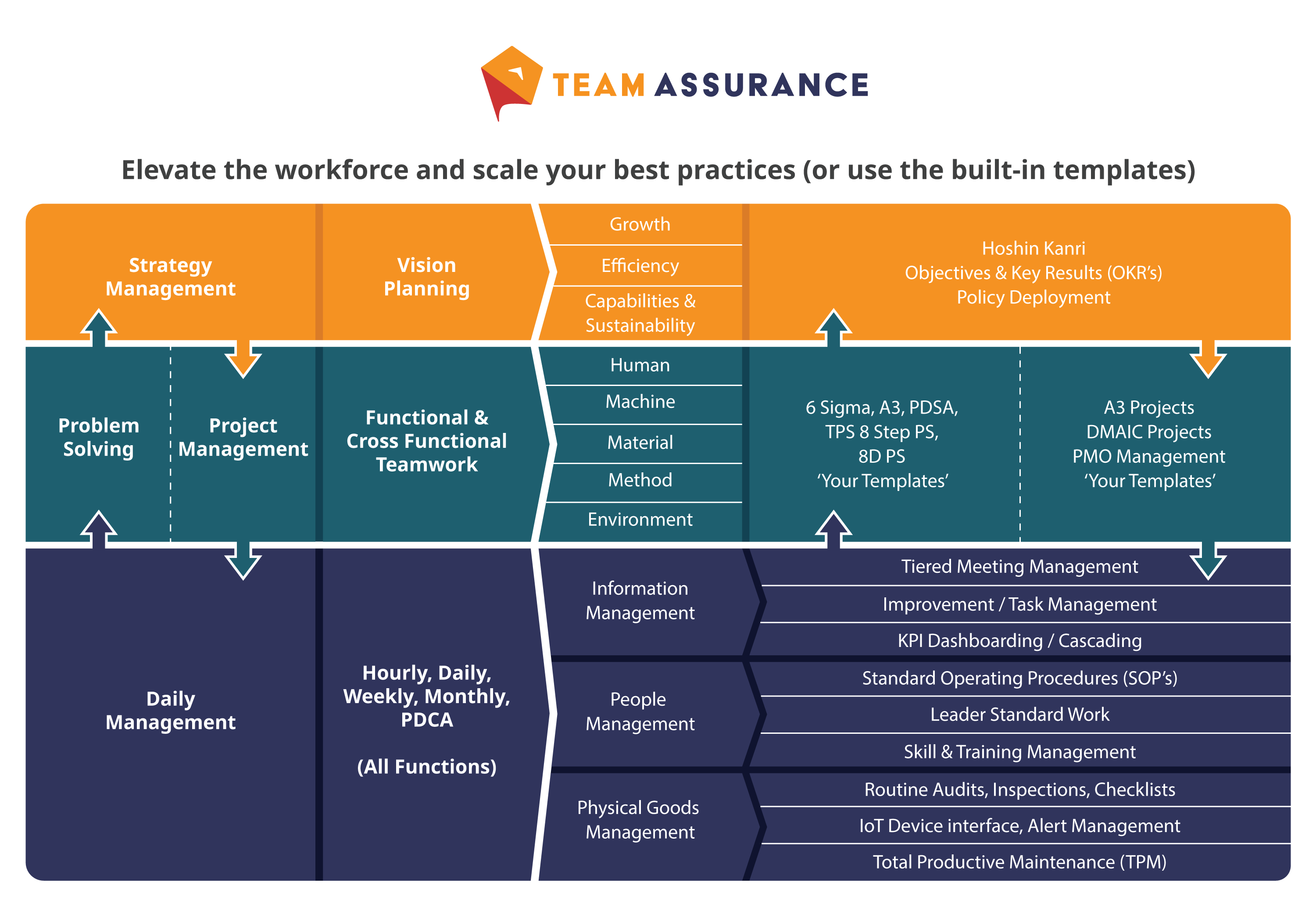

Part of a Continuous Improvement Framework, not a locally optimised ‘Island’

For a process to not thrive (and to be sustained) it must be supported by, and connected to, adjacent processes and systems. Fundamental Lean tools like checklists, and other tools like Leader Standard Work must be supported by standardised problem solving techniques and a Tiered Daily Management process that can handle the full PDCA loop.

The diagram below shows how we designed an interconnected platform that avoids the locally optimised and disconnected ‘Point Solutions’ (digital or analog) which do not help, and may even hinder your progress towards the organisation’s continuous improvement goals.

TeamAssurance Checklists, integrated with action tracking, ensures fast and measurable closing out of issues. If you’re a business in need, or a consultant with clients in need, contact us for a demonstration of the TeamAssurance platform today.

Next read: Introducing TeamAssurance Checklists